STS

Member

- Joined

- Oct 4, 2024

- Messages

- 12

- Location

- KIRKLAND, WA

- Fluid Motion Model

- R-31 S

- Vessel Name

- FESTINA LENTE

Hello, everyone! I’m the new owner of a 2019 Ranger 31S, currently docked on Lake Washington in Kirkland, WA. I'm a 68-year-old retiree, and this is my first boat.

When I bought the boat, the front bilge pump wasn't working—the fuse was blown and breaker was tripping. I tried to remove the pump but quickly realized I'm not the only one struggling to reach it. Here are just two comments from many I found on the Tugnuts forums:

“Anybody know how to get to it other than hiring an NBA player with long arms?”

“You shouldn’t need to be a contortionist to change a bilge pump...”

After several attempts (and quite a few scratches), I could barely touch the red cap of the bilge pump with my middle finger. Just when I started to design some custom pliers using two stainless steel flat bars, I noticed my Canning Jar Lifter Tongs I use for cucumbers and tomato canning (under $9 on Amazon). That was it!

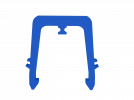

After a few hours of trial and error, I 3D-printed the right adapter on my Flashforge 3 Pro using PLA. I headed to the boat, and in a minute, I had the pump removed! After testing it a few more times, the adapter broke on the fourth attempt, but that’s fine with me—I can always print a new one as needed.

For those interested, I used Fusion 360 for design and Flashforge 5 software for slicing. I’ve attached the STL, GX, and design screenshots. If you plan to use it multiple times, consider using a Nylon filament for added durability.

One tip: When installing a new pump, keep the high-water alarm and bilge pump wires in separate split loom tubing. That way, you won’t have to unscrew the alarm sensor the next time you need to replace the bilge pump.

When I bought the boat, the front bilge pump wasn't working—the fuse was blown and breaker was tripping. I tried to remove the pump but quickly realized I'm not the only one struggling to reach it. Here are just two comments from many I found on the Tugnuts forums:

“Anybody know how to get to it other than hiring an NBA player with long arms?”

“You shouldn’t need to be a contortionist to change a bilge pump...”

After several attempts (and quite a few scratches), I could barely touch the red cap of the bilge pump with my middle finger. Just when I started to design some custom pliers using two stainless steel flat bars, I noticed my Canning Jar Lifter Tongs I use for cucumbers and tomato canning (under $9 on Amazon). That was it!

After a few hours of trial and error, I 3D-printed the right adapter on my Flashforge 3 Pro using PLA. I headed to the boat, and in a minute, I had the pump removed! After testing it a few more times, the adapter broke on the fourth attempt, but that’s fine with me—I can always print a new one as needed.

For those interested, I used Fusion 360 for design and Flashforge 5 software for slicing. I’ve attached the STL, GX, and design screenshots. If you plan to use it multiple times, consider using a Nylon filament for added durability.

One tip: When installing a new pump, keep the high-water alarm and bilge pump wires in separate split loom tubing. That way, you won’t have to unscrew the alarm sensor the next time you need to replace the bilge pump.