Rocky Lou

Well-known member

- Joined

- Aug 2, 2019

- Messages

- 465

- Fluid Motion Model

- C-302 C

- Vessel Name

- Sea Suite

For those who haven't seen it already there is an excellent thread on PowerTech SCE/Modified props: https://www.tugnuts.com/threads/r27-ob-propeller-testing-results-are-in.24353/. You will find a great of deal of data showing significantly improved performance for R25/27 single Yamaha engines.

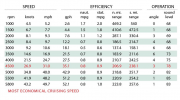

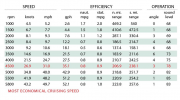

I've been quite happy with my Cutwater C302c LE that I bought new in 2019 with a few big exceptions. The performance, as I compared to other boats of similar size and weight was terrible with stern drag being a key factor, particularly with my model that has a heavy generator located aft. The chart below, from Boating Mag., is consistent with the kind of performance that I was getting. In particular, at 3500 RPM, I got a paltry 16 MPH. Props were: Twin F300’s - Saltwater Series II - 19-TL, 15.25.

So, for the past few years, I've been trying to improve performance. I got a quick win, albeit small, from adding drop fins that BB has advocated. I recently removed my Lenco trim tabs, that were aging and the well used drop fins had fallen off, with new 12x24 inch Bennett Trim Tabs that have drop fins one piece design. Again, they are worth having, but, do very little to help performance.

I investigated other props, notably spending two years testing Sharrow, then, moving onto PowerTech. I am currently running PowerTech OFS5, 17 pitch that provide considerable stern lift.

——————————————————————————————

Here is what I noted yesterday running the PowerTech 5 blade props:

Based on the SCE/Modified post, I installed two props recently.

Unfortunately, the first trial run was a quick trip. The 14 inch props had no where near the much needed stern lift that the current OFS5 props

have and the mid range results were much worse.

Some of the key comparisons:

3500 RPM: SCE: 19 MPH, .9 MPG vs. OFS5: 24 MPH .9 to 1.2 MPG

4000 RPM: SCE: 26 MPH, .9 MPG vs. OFS5: 30 MPh, .9 to 1.2 MPG

The one area of improvement was WOT where I could get up to 5800 RPM with SCE and 44 MPH.

Speaking with PowerTech, they advised the the 'modification' that is their Patent Pending extension tubes (well described by Submariner) could be added to my OFS5s and will add some stern lift. I then agreed to test another set of OFS5 16 pitch with extensions to see if I can maintain the mid range performance and get the top end back to the normal operating range. While I was prepared to 'declare victory' with the OFS5 17s, since I rarely need top speed, they wanted to give it one more shot that I'll report once completed. In all, PowerTech is a great company to work with, have products that significantly improve performance over Yamaha SS2s, and only cost about $1K per copy.

I've been quite happy with my Cutwater C302c LE that I bought new in 2019 with a few big exceptions. The performance, as I compared to other boats of similar size and weight was terrible with stern drag being a key factor, particularly with my model that has a heavy generator located aft. The chart below, from Boating Mag., is consistent with the kind of performance that I was getting. In particular, at 3500 RPM, I got a paltry 16 MPH. Props were: Twin F300’s - Saltwater Series II - 19-TL, 15.25.

So, for the past few years, I've been trying to improve performance. I got a quick win, albeit small, from adding drop fins that BB has advocated. I recently removed my Lenco trim tabs, that were aging and the well used drop fins had fallen off, with new 12x24 inch Bennett Trim Tabs that have drop fins one piece design. Again, they are worth having, but, do very little to help performance.

I investigated other props, notably spending two years testing Sharrow, then, moving onto PowerTech. I am currently running PowerTech OFS5, 17 pitch that provide considerable stern lift.

——————————————————————————————

Here is what I noted yesterday running the PowerTech 5 blade props:

- RPM, MPH, GPH

- 1000, 6 2.1

- 1500, 8 1.6

- 2000,10 1.2

- 2500, 12 0.7 to 0.9

- 3000, 16 0.9 tabs deployed

- 3500, 24 0.9 to 1.2

- 4000, 30 0.9 to 1.2

- 4500, 35 0.9

- 5000, 41, 0.7

- 5400WOT 44, 0.7

- Getting on plane happened at much lower RPM

- Mid range performance improved 25-30%

- Trim Tabs need to be put to full down position to maintain control (this is normal) and tilt/trim was full down and not touched

Based on the SCE/Modified post, I installed two props recently.

Unfortunately, the first trial run was a quick trip. The 14 inch props had no where near the much needed stern lift that the current OFS5 props

have and the mid range results were much worse.

Some of the key comparisons:

3500 RPM: SCE: 19 MPH, .9 MPG vs. OFS5: 24 MPH .9 to 1.2 MPG

4000 RPM: SCE: 26 MPH, .9 MPG vs. OFS5: 30 MPh, .9 to 1.2 MPG

The one area of improvement was WOT where I could get up to 5800 RPM with SCE and 44 MPH.

Speaking with PowerTech, they advised the the 'modification' that is their Patent Pending extension tubes (well described by Submariner) could be added to my OFS5s and will add some stern lift. I then agreed to test another set of OFS5 16 pitch with extensions to see if I can maintain the mid range performance and get the top end back to the normal operating range. While I was prepared to 'declare victory' with the OFS5 17s, since I rarely need top speed, they wanted to give it one more shot that I'll report once completed. In all, PowerTech is a great company to work with, have products that significantly improve performance over Yamaha SS2s, and only cost about $1K per copy.

Last edited: